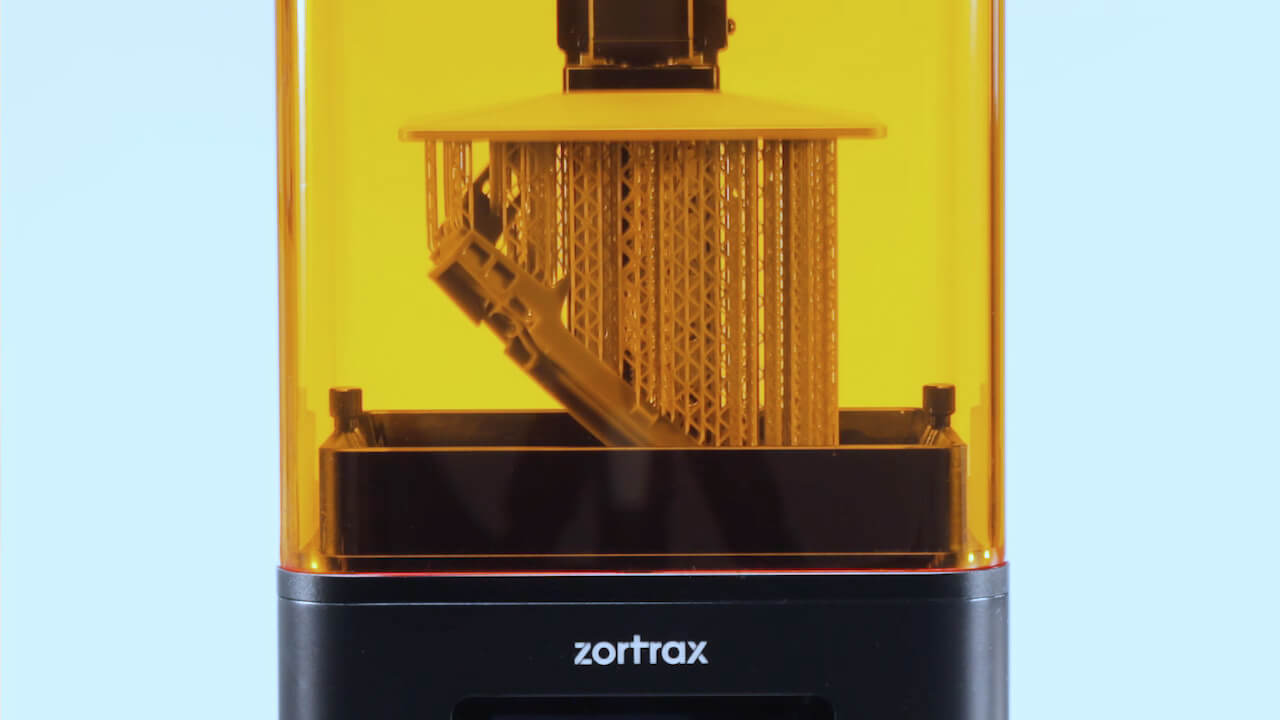

Step 1 3D print

A model is made layer-by-layer out of a photopolymer solidified by UV light.

The technology behind Zortrax Inkspire relies on a high resolution LCD screen with UV LED backlighting to cure photopolymers layer by layer.

SLA and DLP are traditional resin 3D printing technologies. An SLA printer works at constant precision but the more of its workspace is used, the more it slows down. In DLP machines, the speed is constant but precision decreases when workspace usage grows. Zortrax UV LCD maintains both high speed and precision at all times.

A layer is drawn

with laser

A layer is projected by

a digital projector

A layer is projected on a high-res

LCD screen with UV LED

backlighting*

Zortrax Inkspire is made for all applications where superior precision is of paramount importance. The human eye can't see individual pixels when the image has more than 336 pixels per inch. Pixel density in models 3D printed on the Inkspire exceeds this value regardless of the viewing angle.

Industrial-grade components used in the Inkspire guarantee surfaces of models are consistently flawless across multiple prints. The printer is designed to achieve the highest possible results repeatability.

Multiple versions of prototypes can be cost-efficiently made in one printing session. This way, they can quickly undergo comparative evaluation which saves costs by shortening the development cycle.

The Inkspire easily scales up to work in 3D printing farms offering medium to high scale manufacturing capabilities. Such farms can make end-use products or serve as a support of traditional production lines.

An advanced optical system guarantees almost perfectly even distribution of UV light across the build platform. That's why the Inkspire is one of the fastest resin 3D printers on the market without compromising any of the print's quality.

A model is made layer-by-layer out of a photopolymer solidified by UV light.

Innovative technology makes support structures easy to remove.

A 3D printed model can be used in further prototyping stages or shipped as a fully functional product.

Resin 3D printing is a technology perfect for professionals working in fields where very small yet incredibly detailed models are needed. The precision and speed of Zortrax Inkspire makes it a game changing tool for engineers, dentists and jewelers among others.

Resin 3D printers can quickly and cost-efficiently print dental impressions, surgical guides, and temporary crowns or bridges.

3D printed jewelry models can be used as investment casting patterns. They are also useful in customer consultation and fitting.

Small, intricately designed 3D printed parts can be used in various fields of precision engineering such as electronics design.

3D printing of complex organic shapes is commonly used for making early concept models in production of feature movies and TV shows.